Digital Twins: Revolutionizing Automotive Design and Engineering

Digital twins are revolutionizing automotive design and engineering by providing virtual replicas of vehicles and their components, enabling manufacturers to simulate, test, and optimize performance in a virtual environment before physical prototypes are even built.

The automotive industry is undergoing a massive transformation, driven by innovation and the need for greater efficiency. One of the most disruptive technologies playing a key role in this evolution is the use of digital twins. But how exactly are these virtual replicas transforming automotive design and engineering, and what benefits do they offer for the future of vehicle development?

Understanding Digital Twins in the Automotive Context

Digital twins are more than just 3D models; they are dynamic virtual representations of physical objects, systems, or processes. In the automotive industry, this means creating a complete digital replica of a vehicle, its components, and even its manufacturing processes.

This replica allows engineers to simulate real-world conditions, test designs, and optimize performance without the need for physical prototypes, reducing costs and accelerating the development cycle.

Key Components of a Digital Twin

The sophistication of automotive digital twins comes from their multifaceted composition, which merges several data streams to provide a holistic virtual prototype.

- 3D Models: High-fidelity geometric representations capture the accurate physical attributes of the car and its components.

- Sensor Data: Actual performance metrics from sensors on real-world counterparts flow into the digital twin, providing real-time feedback.

- Simulation Tools: Integrated simulation software analyzes the impact of various conditions on the digital twin, forecasting performance.

Benefits of Using Digital Twins

Implementing digital twins comes with multiple advantages, transforming traditional automotive practices by offering greater design precision and effectiveness.

- Cost Savings: Reduces the expensive and time-consuming necessity for numerous real prototypes.

- Time Efficiency: Expedites the engineering process, enabling faster market entry.

- Enhanced Quality: Provides the capability to detect and fix flaws early in the design stages.

In conclusion, employing digital twins in the automotive sector leads to more efficient, cost-effective, and high-quality car design and manufacturing practices, improving productivity and design quality.

Revolutionizing the Design Phase

Digital twins are making a significant impact on the automotive design phase, enabling designers and engineers to collaborate more effectively, explore new ideas, and validate their designs in a virtual environment.

This virtual approach fosters innovation and reduces the reliance on physical prototypes, leading to more efficient and cost-effective design processes.

Virtual Prototyping and Testing

With digital twins, engineers can create virtual prototypes that accurately represent the physical characteristics and behavior of a vehicle.

These virtual prototypes can be subjected to a wide range of tests and simulations, allowing engineers to identify potential design flaws, optimize performance, and improve safety without the need for physical testing.

Collaboration and Communication

Digital twins facilitate better collaboration and communication between different teams involved in the design process.

Designers, engineers, and even marketing teams can access and interact with the digital twin, providing valuable feedback and insights that can be incorporated into the design.

In essence, digital twins are transforming the automotive design phase by allowing for more comprehensive testing, better collaboration, and faster iteration cycles, ultimately leading to better and more innovative vehicle designs.

Optimizing Vehicle Performance

Beyond the design phase, digital twins play a crucial role in optimizing vehicle performance. By simulating real-world driving conditions and analyzing vehicle data, engineers can fine-tune various aspects of a vehicle’s performance.

This optimization leads to improved fuel efficiency, enhanced handling, and a more comfortable driving experience.

Aerodynamic Simulations

Digital twins enable engineers to conduct detailed aerodynamic simulations, evaluating how a vehicle interacts with airflow.

These simulations help optimize the vehicle’s shape and design to minimize drag, improve fuel efficiency, and enhance stability at high speeds.

Powertrain Optimization

Digital twins can be used to simulate the performance of a vehicle’s powertrain under different driving conditions.

- Optimize fuel consumption

- Improve acceleration

- Reduce emissions.

Suspension and Handling

Engineers can simulate the behavior of a vehicle’s suspension system and handling characteristics using digital twins.

- Optimizing ride comfort

- Improving handling responsiveness

- Enhancing overall vehicle stability.

Digital twins offer invaluable capabilities for optimizing vehicle performance by replicating and assessing vehicle reactions in various realistic circumstances.

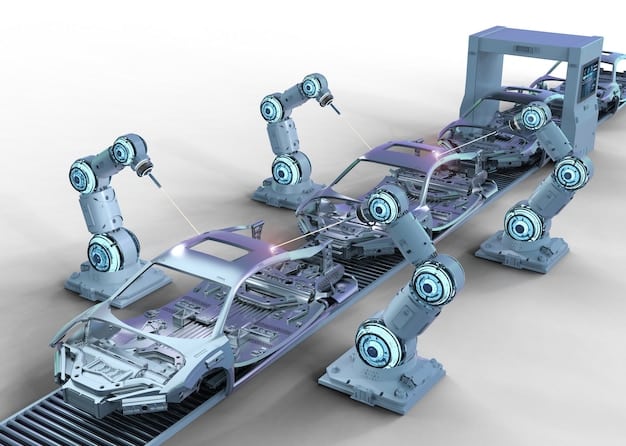

Enhancing Manufacturing Processes

Digital twins extend their influence beyond design and performance optimization, revolutionizing the manufacturing processes within the automotive industry.

By creating digital replicas of production lines and manufacturing equipment, automakers can streamline their operations, reduce downtime, and improve overall efficiency.

Predictive Maintenance

Digital twins can monitor the condition of manufacturing equipment and predict potential failures before they occur.

By analyzing sensor data and historical performance data, digital twins can identify patterns and anomalies that indicate a need for maintenance, preventing costly downtime and ensuring continuous production.

Process Optimization

Digital twins allow manufacturers to simulate and optimize their production processes in a virtual environment.

By identifying bottlenecks, streamlining workflows, and optimizing resource allocation, automakers can improve efficiency, reduce costs, and increase throughput.

Quality Control

Digital twins can be used to monitor and control the quality of manufactured products.

By comparing the digital twin of a product to its physical counterpart, manufacturers can identify deviations from the intended design and detect potential defects early in the manufacturing process.

Automotive manufacturers are leveraging digital twins to greatly enhance their manufacturing operations, improving efficiency and cost-effectiveness.

The Future of Automotive Engineering with Digital Twins

As digital twin technology continues to evolve, its role in automotive engineering is only going to grow, impacting everything from design to production and even after-sales service.

The convergence of digital twins with other emerging technologies like AI and IoT will unlock new possibilities and further transform the automotive industry.

AI-Powered Optimization

Integrating AI algorithms into digital twins enables real-time optimization and adaptive learning.

AI can analyze vast amounts of data generated by the digital twin to identify patterns, predict outcomes, and automatically adjust parameters to improve performance, efficiency, and reliability.

IoT Connectivity

Connecting digital twins to IoT devices and sensors in vehicles allows for continuous monitoring and data collection.

This real-time data can be used to update the digital twin, improve its accuracy, and provide valuable insights into vehicle performance, driver behavior, and environmental conditions.

Customization and Personalization

Digital twins enable greater customization and personalization of vehicles.

By creating a digital twin of each individual vehicle, automakers can tailor features, performance, and services to meet the unique needs and preferences of the owner.

Using AI, IOT, and customization, the prospects are boundless to enhance digital twin competencies within automotive manufacturing, streamlining design process and improving vehicle quality and performance.

Overcoming Challenges in Implementing Digital Twins

Despite the numerous benefits, implementing digital twins in automotive engineering also presents several challenges.

Addressing these challenges is crucial for realizing the full potential of digital twin technology and ensuring its successful adoption across the industry.

Data Management

Digital twins generate vast amounts of data that need to be stored, processed, and analyzed effectively.

Developing robust data management strategies and infrastructure is essential for handling the volume, velocity, and variety of data generated by digital twins.

Integration Complexity

Integrating digital twins with existing engineering tools, systems, and processes can be complex and time-consuming.

Ensuring seamless interoperability and data exchange between different systems is crucial for realizing the full value of digital twins.

Skills Gap

Developing and implementing digital twins requires specialized skills and expertise.

- Training existing employees

- Hiring new talent with the necessary skills.

Overcoming issues such as data handling, integration, and skillset will promote further adoption of digital twins in the automotive industry.

| Key Point | Brief Description |

|---|---|

| 💡 Design Revolution | Virtual prototypes allow for quick design iteration and testing. |

| ⚙️ Performance Optimization | Digital twins fine-tune aerodynamics and powertrain performance. |

| 🏭 Manufacturing Efficiency | Predictive maintenance and process optimization reduce downtime. |

| 🔮 Future Trends | AI enhances digital twins, improving personalization and performance. |

Section FAQ

▼

A digital twin is a virtual representation of a physical vehicle, component, or system. It allows engineers to simulate, test, and optimize performance in a virtual environment.

▼

Digital twins allow designers to create virtual prototypes, test different design options, and identify potential issues early in the development process, reducing the need for physical prototypes and saving time and money.

▼

Digital twins simulate real-world driving conditions to analyze a vehicle’s aerodynamic performance, powertrain efficiency, and handling, all of which leads to optimized fuel economy, handling, and comfort.

▼

Digital twins can watch for equipment condition and predict potential machine failures, simulating and optimizing production processes to improve efficiency and quality control of all products.

▼

Handling vast amounts of data from digital twins, integrating them with tools and other systems, and providing effective employee training are key challenges to overcome in its use.

Conclusion

In conclusion, digital twins are revolutionizing automotive design and engineering by enabling virtual testing, optimizing performance, and streamlining manufacturing processes. This transformative technology is poised to shape the future of the automotive industry, driving innovation and efficiency across all facets of vehicle development.