Digital Twins in Automotive: Revolutionizing Design & Engineering

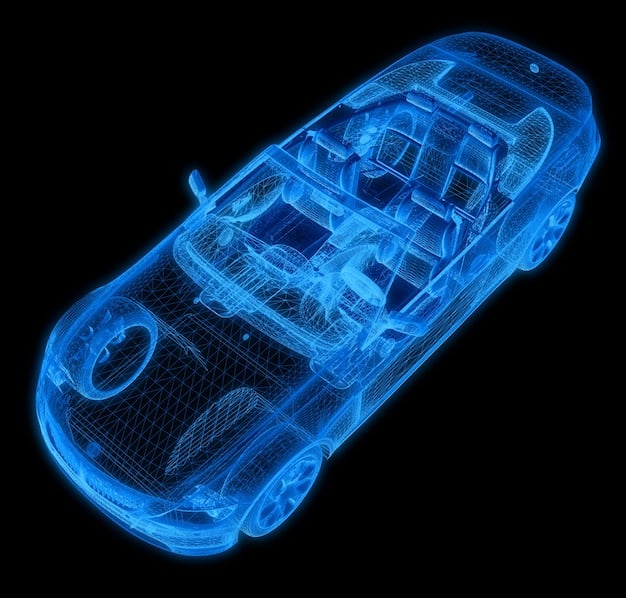

Digital twins are revolutionizing automotive design and engineering by providing virtual replicas of vehicles and components, enabling real-time simulation, testing, and optimization, ultimately leading to faster development cycles, improved performance, and reduced costs.

The automotive industry is undergoing a massive transformation, and at the forefront of this revolution is the application of digital twins. These virtual replicas of vehicles, systems, and components are changing the way cars are designed, engineered, and manufactured, offering unprecedented opportunities for innovation and efficiency.

How Digital Twins are Reshaping Automotive Design

Digital twins are no longer a futuristic concept; they are a present-day reality transforming automotive design. By creating comprehensive virtual models, digital twins enable engineers to simulate and analyze vehicle performance in various conditions, identify potential design flaws early in the development process, and optimize designs for enhanced efficiency and safety.

Virtual Prototyping and Testing

Digital twins allow automakers to significantly reduce their reliance on physical prototypes. This virtual prototyping and testing environment accelerates the design cycle and reduces costs associated with building and testing physical models.

Real-time Monitoring and Optimization

By connecting to real-world data from sensors on vehicles, digital twins provide real-time insights into vehicle performance. This allows for continuous monitoring and optimization, ensuring that vehicles operate at peak efficiency and safety.

- Early Defect Detection: Identify and rectify design flaws before physical production begins.

- Performance Optimization: Continuously refine designs based on real-world data to enhance fuel efficiency and handling.

- Reduced Development Time: Accelerate the design process by minimizing the need for physical prototypes and testing.

The adoption of digital twins in automotive design is driving innovation and efficiency, enabling automakers to create better, safer, and more sustainable vehicles. These virtual models are becoming an indispensable tool for engineers, designers, and manufacturers looking to stay ahead in a rapidly evolving industry.

The Role of Digital Twins in Automotive Engineering

Digital twins are playing a critical role in automotive engineering by providing a platform for collaboration and knowledge sharing across different teams and departments. These virtual models facilitate better communication and coordination, leading to more efficient engineering processes and improved product quality.

Enhancing Collaboration and Communication

Digital twins serve as a central hub for all engineering-related data, allowing different teams to access and work with the same information. This eliminates silos and fosters collaboration, leading to more integrated and efficient engineering workflows.

Predictive Maintenance and Diagnostics

By analyzing data from sensors on vehicles, digital twins can predict potential maintenance issues before they occur. This allows for proactive maintenance, reducing downtime and extending the lifespan of vehicles.

- Improved Communication: Facilitate seamless communication and collaboration between design, engineering, and manufacturing teams.

- Enhanced Predictive Maintenance: Anticipate potential maintenance issues and schedule repairs proactively.

- Streamlined Engineering Processes: Optimize engineering workflows and reduce inefficiencies through real-time data analysis.

Digital twins are revolutionizing automotive engineering by enabling better collaboration, predictive maintenance, and streamlined processes. As the complexity of vehicles continues to increase, digital twins will become even more essential for ensuring efficient and effective engineering practices.

Improving Manufacturing Processes with Digital Twins

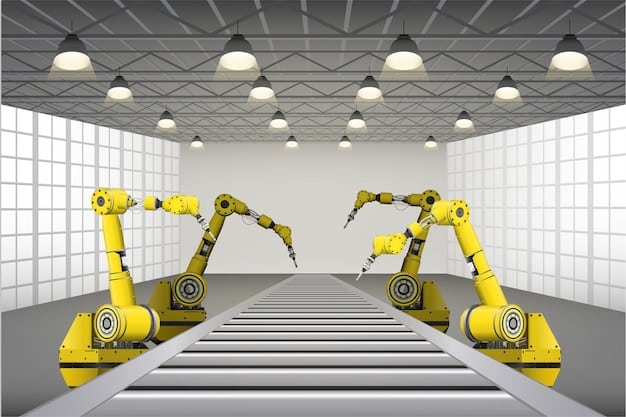

Digital twins are not just transforming design and engineering; they are also revolutionizing manufacturing processes in the automotive industry. By creating virtual replicas of factories, production lines, and equipment, digital twins enable manufacturers to optimize their operations, reduce waste, and improve overall efficiency.

Factory Simulation and Optimization

Digital twins allow manufacturers to simulate and optimize their factory layouts, production flows, and resource allocation. This enables them to identify bottlenecks, improve efficiency, and reduce costs.

Predictive Maintenance of Equipment

By monitoring the performance of equipment using sensors, digital twins can predict potential maintenance issues before they lead to downtime. This allows for proactive maintenance, maximizing uptime and reducing the risk of costly disruptions.

The use of digital twins in manufacturing is enabling automakers to create more efficient, resilient, and sustainable production systems. This technology is transforming the way cars are built, paving the way for the factory of the future.

Cost Reduction Through Digital Twin Technology

One of the most significant benefits of digital twins is their ability to drive down costs throughout the automotive value chain. By reducing the need for physical prototypes, optimizing manufacturing processes, and enabling predictive maintenance, digital twins are helping automakers save millions of dollars.

Reducing Prototyping Costs

Digital twins allow manufacturers to perform extensive testing, validation and research without investing heavily in physical prototypes.

Optimizing Resources

By integrating real-time data from multiple sources, digital twins offer information that streamlines production and the use of resources.

- Reduced Waste: Optimize material usage and minimize waste through virtual simulation.

- Lower Energy Consumption: Reduce energy consumption by optimizing manufacturing processes.

- Improved Supply Chain Management: Enhance supply chain visibility and coordination, reducing costs associated with delays and disruptions.

The cost-saving potential of digital twins is driving their adoption across the automotive industry. As automakers face increasing pressure to reduce costs and improve efficiency, digital twins will become an even more critical tool for achieving these goals.

Enhancing Vehicle Performance and Efficiency

Digital twins are not only transforming the way cars are designed and manufactured, but they are also enhancing vehicle performance and efficiency. By providing real-time data and insights, digital twins enable engineers to optimize vehicle systems for improved fuel economy, handling, and safety.

Optimizing Engine Performance

By modeling the factors of the engine and collecting real-time data, the optimal level of performance and efficiency can be extracted.

Improving Aerodynamics

Digital twins can accurately simulate the vehicle’s aerodynamic performance resulting in higher speeds and optimized fuel economy.

Digital twins are helping automakers create vehicles that are more efficient, sustainable, and enjoyable to drive. As the industry continues to embrace electrification and autonomous driving, digital twins will play an increasingly important role in optimizing vehicle performance and ensuring driver safety.

Future Trends and Opportunities with Digital Twins

The future of digital twins in the automotive industry is bright, with numerous opportunities for further innovation and advancement. As technology evolves, digital twins will become even more integrated into the automotive value chain, enabling automakers to create more intelligent, connected, and sustainable vehicles.

Autonomous Vehicle Development

Digital twins are facilitating the development of autonomous vehicles by providing a safe and cost-effective environment for testing and validating self-driving systems.

Electrification and Battery Management

Digital twins are enabling automakers to optimize the design and performance of electric vehicles, including battery management systems, charging infrastructure, and energy efficiency.

The continued evolution of digital twin technology will unlock new opportunities for innovation, efficiency, and sustainability in the automotive industry. As automakers embrace these advancements, they will be able to create vehicles that are safer, more efficient, and more enjoyable to drive.

| Key Point | Brief Description |

|---|---|

| ⚙️ Virtual Prototyping | Reduces reliance on physical prototypes, cutting costs and accelerating design cycles. |

| 🤝 Enhanced Collaboration | Facilitates better communication between different teams involved in automotive engineering. |

| 🛠️ Predictive Maintenance | Analyzes sensor data to anticipate maintenance needs, reducing downtime. |

| ⚡ Electrification | Optimizes design and performance of electric vehicles, including battery management systems. |

Frequently Asked Questions

▼

A digital twin is a virtual replica of a physical vehicle, system, or component. It mirrors real-world elements and allows for simulations, testing, and analysis in a virtual environment.

▼

Digital twins minimize the need for physical prototypes, optimize manufacturing processes, and enable predictive maintenance, which avoids costly downtime and repairs.

▼

Yes, they allow engineers to optimize vehicle systems for improved fuel economy, streamlined handling, and enhanced safety through real-time data and detailed simulations.

▼

Absolutely, digital twins offer a safe and cost-effective environment to test and validate self-driving systems before real-world deployment, ensuring greater reliability.

▼

They provide a centralized hub for all engineering-related data. This facilitates seamless communication and knowledge sharing of all engineering-related aspects between various teams.

Conclusion

Digital twins are transforming the automotive industry by revolutionizing design, engineering, and manufacturing processes. As automakers continue to embrace this technology, they will be able to create better, safer, and more sustainable vehicles.