AI Revolution: Transforming Car Manufacturing Processes in the US

Artificial intelligence (AI) is transforming car manufacturing processes in the US by automating tasks, improving quality control, optimizing supply chains, and enhancing design and personalization, leading to greater efficiency and innovation.

The automotive industry is undergoing a dramatic transformation, and at the heart of this change lies artificial intelligence (AI) is revolutionizing car manufacturing processes. The integration of AI is not just a futuristic concept; it’s a present-day reality that’s reshaping how cars are designed, built, and delivered in the US.

How AI is Reshaping US Car Design

AI is changing how cars are designed. It helps engineers create better, safer, and more efficient vehicles.

The use of AI in car design is revolutionizing the industry. Its ability to rapidly analyze and iterate designs, coupled with its capacity to personalize vehicle features, is making the impossible, possible.

Generative Design

AI algorithms can generate multiple design options based on specific parameters. This accelerates the design process and allows engineers to explore innovative solutions.

Virtual Prototyping

AI enables virtual testing of designs, reducing the need for physical prototypes. This saves time and resources while improving the overall design quality.

- Faster Design Cycles: AI significantly reduces the time required for design iteration, allowing companies to bring new models to market more quickly.

- Improved Performance: AI-driven design tools optimize vehicle performance, enhancing fuel efficiency, aerodynamics, and structural integrity.

- Customization Options: AI facilitates personalized car designs based on individual customer preferences, leading to greater customer satisfaction.

AI’s impact on car design is profound, enabling manufacturers to create vehicles that are not only more efficient but also tailored to meet the unique needs and preferences of consumers. The future of car design is undeniably intertwined with the continued advancement and integration of AI technologies.

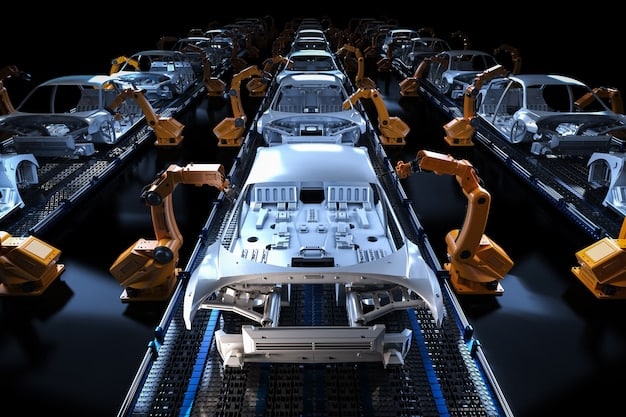

AI-Powered Automation in Car Assembly Lines

AI is increasingly critical in automating tasks, ensuring precision, and improving overall efficiency.

The integration of AI in car assembly lines is transforming manufacturing processes, making them more efficient, precise, and safe. AI-powered robots and systems are streamlining operations.

Robotic Assembly

AI-powered robots perform repetitive and complex tasks with greater precision and speed than humans. This reduces errors and increases production volume.

Predictive Maintenance

AI algorithms analyze data from machinery to predict potential maintenance needs. This minimizes downtime and extends the lifespan of equipment.

- Increased Efficiency: AI-driven automation reduces production time and increases output, leading to significant cost savings.

- Enhanced Quality Control: AI systems can detect defects in real-time, ensuring that only high-quality vehicles reach the market.

- Safer Working Conditions: Robots handle hazardous tasks, reducing the risk of injury for human workers.

AI’s role in automating car assembly lines is enhancing productivity, quality, and safety. As AI technology continues to advance, its integration into manufacturing processes will become even more prevalent, driving further improvements in the industry.

Enhancing Quality Control with AI Vision Systems

AI is revolutionizing quality control in car manufacturing through the use of advanced vision systems. These systems ensure that every vehicle meets the highest standards of quality.

AI vision systems are transforming quality control processes, enabling manufacturers to identify and address defects with greater accuracy and speed. This leads to improved product quality and customer satisfaction.

Real-Time Defect Detection

AI vision systems use cameras and machine learning algorithms to inspect vehicles for defects in real-time. This allows for immediate corrective action.

Automated Inspection

AI automates the inspection process, reducing the need for manual inspections. This saves time and resources while improving accuracy.

- Superior Accuracy: AI vision systems can detect even the smallest defects that may be missed by human inspectors, ensuring higher quality standards.

- Reduced Costs: By automating the inspection process, AI helps reduce labor costs and minimize errors, leading to significant savings.

- Improved Consistency: AI provides consistent and reliable inspections, ensuring that every vehicle meets the same high standards.

AI vision systems are essential for maintaining high quality standards in car manufacturing. As AI technology continues to evolve, its integration into quality control processes will become even more sophisticated, further enhancing product reliability and customer satisfaction.

Optimizing Supply Chain Management with AI

AI is playing a crucial role in optimizing supply chain management in car manufacturing. It enhances efficiency and reduces costs.

The implementation of AI in supply chain management is transforming how car manufacturers manage their resources, logistics, and inventory. This leads to greater efficiency and responsiveness.

Demand Forecasting

AI algorithms analyze historical data and market trends to accurately forecast demand. This helps manufacturers optimize production schedules and inventory levels.

Logistics Optimization

AI optimizes transportation routes and delivery schedules, reducing costs and minimizing delays. This ensures that parts and materials are delivered on time.

- Reduced Inventory Costs: AI-driven demand forecasting minimizes excess inventory, freeing up capital and reducing storage expenses.

- Improved Delivery Times: AI optimizes logistics, ensuring that parts and materials are delivered quickly and efficiently, reducing production bottlenecks.

- Enhanced Collaboration: AI facilitates better communication and collaboration between suppliers, manufacturers, and distributors, improving overall supply chain performance.

AI’s impact on supply chain management is significant, enabling car manufacturers to operate more efficiently and respond quickly to changing market conditions. As AI technology continues to advance, its integration into supply chain processes will become even more critical for maintaining a competitive edge.

Personalization and Customization Through AI

AI enables car manufacturers to offer personalized and customized options to customers. AI enhances customer satisfaction and loyalty.

AI is revolutionizing how car manufacturers approach personalization and customization, offering customers a range of options tailored to their individual preferences. This enhances customer satisfaction and drives loyalty.

Custom Design Options

AI-driven design tools allow customers to personalize the appearance and features of their vehicles. This includes selecting colors, materials, and accessories.

Adaptive Features

AI enables cars to adapt to the driver’s preferences, such as seat settings, climate control, and entertainment options. This provides a more comfortable and personalized driving experience.

- Increased Customer Satisfaction: Personalized options make customers feel valued and understood, leading to greater satisfaction and loyalty.

- Higher Sales: The ability to customize vehicles encourages customers to purchase higher-value models with more features.

- Competitive Advantage: Offering personalized options sets car manufacturers apart from competitors, attracting customers who seek unique and tailored experiences.

AI’s role in personalization and customization is transforming the car buying experience, making it more engaging and satisfying for customers. As AI technology continues to evolve, its integration into personalization processes will become even more sophisticated, further enhancing customer relationships and driving sales.

The Future of AI in US Car Manufacturing

AI is poised to play an even greater role in car manufacturing in the future. This drives innovation and efficiency.

The future of AI in car manufacturing is bright, with ongoing advancements promising to further transform the industry. From enhanced automation to more sophisticated personalization, AI is set to drive innovation and efficiency.

Advanced Robotics

Future AI systems will power even more advanced robots capable of performing complex tasks with greater autonomy. This will further streamline manufacturing processes.

Predictive Analytics

AI will use predictive analytics to optimize every aspect of car manufacturing, from design to supply chain management. This will lead to greater efficiency and cost savings.

- Greater Automation: AI-driven automation will continue to expand, reducing the need for human intervention and increasing production output.

- Improved Sustainability: AI will optimize resource usage and reduce waste, making car manufacturing more sustainable.

- Enhanced Safety: AI will improve safety by predicting and preventing accidents in the workplace, creating a safer environment for human workers.

AI’s future in car manufacturing is marked by continuous innovation and improvement. As AI technology evolves, its integration into manufacturing processes will become even more seamless and transformative, driving the industry towards greater efficiency, sustainability, and safety.

| Key Point | Brief Description |

|---|---|

| 🎨 AI in Design | AI accelerates car design and enables virtual prototyping. |

| 🤖 Automation | Robots perform tasks with precision, increasing efficiency. |

| 🔍 Quality Control | AI vision systems detect defects, ensuring high standards. |

| 📦 Supply Chain | AI optimizes logistics for better efficiency and cost savings. |

Frequently Asked Questions

▼

AI enhances car design through generative design and virtual prototyping, enabling faster design cycles and improved performance. It also allows more customization options based on customer preferences.

▼

AI-powered robots automate repetitive tasks, enhance quality control, and predict maintenance needs. This increases efficiency, reduces errors, and improves worker safety in the assembly process.

▼

AI vision systems use cameras and machine learning to detect defects in real-time. This automates inspections, provides superior accuracy, and ensures consistent quality standards in manufacturing.

▼

AI optimizes supply chain management through demand forecasting and logistics optimization. This reduces inventory costs, improves delivery times, and enhances collaboration among suppliers and manufacturers, increasing efficiency.

▼

AI enables customers to personalize design options and adapt vehicle features to their preferences, resulting in increased satisfaction. This also helps offer unique and tailored experiences, leading to greater customer loyalty.

Conclusion

Artificial intelligence (AI) is revolutionizing car manufacturing processes in the US, driving innovation, efficiency, and personalization. From design to assembly, supply chain management, and quality control, AI is transforming every aspect of the industry, promising a future where cars are better, safer, and more tailored to individual needs.