Digital Twins Revolution: Transforming Automotive Design & Engineering

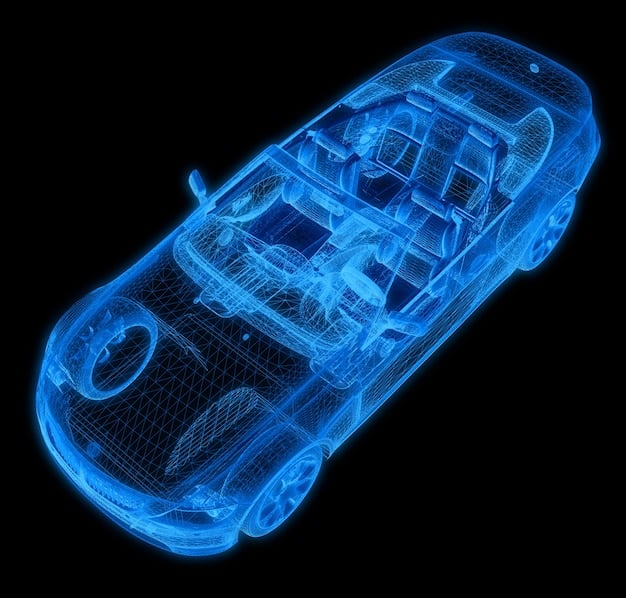

Digital twins are revolutionizing the automotive industry by providing virtual replicas of vehicles and components, enabling manufacturers to simulate, test, and optimize designs in a cost-effective and efficient manner.

The automotive industry is undergoing a massive transformation, driven by technological advancements and the need for greater efficiency. Among these innovations, digital twins are transforming automotive design and engineering by creating virtual replicas of vehicles, systems, and components. This technology allows for comprehensive simulations, testing, and optimization before a physical prototype even exists.

What Are Digital Twins and Why Are They Important?

Digital twins are virtual representations of physical objects or systems. They leverage data from sensors, simulations, and historical information to create a dynamic model that mirrors the real-world counterpart. In the automotive industry, this technology brings numerous benefits.

The adoption of digital twins allows engineers and designers to:

- Reduce development time and costs.

- Improve product quality and performance.

- Enhance collaboration between different teams.

- Predict and prevent potential issues before they occur.

Overall, digital twins are an invaluable asset for car manufacturers looking to stay competitive in a rapidly evolving market.

The Role of Digital Twins in Automotive Design

The design phase of a car’s lifecycle is one of the most crucial steps. Digital twins play a significant role in optimizing this phase, enabling designers to iterate faster and create more innovative products.

Here’s how digital twins contribute to automotive design:

Virtual Prototyping

Digital twins allow for creation of virtual prototypes, eliminating the need for costly and time-consuming physical models. This enables designers to test various design options in a simulated environment, assessing performance, aerodynamics, and aesthetics.

Ergonomics and Human Factors

Digital twins can simulate human interaction with a vehicle’s interior, assessing ergonomics and usability before manufacturing. This ensures that the final product meets the needs and expectations of drivers and passengers.

Digital twins also contribute to:

- Improving cabin comfort and safety.

- Assessing the positioning of controls and displays.

- Optimizing the layout for accessibility and ease of use.

By testing these factors in a virtual environment, companies can mitigate design flaws and enhance product quality.

Engineering Benefits: Simulation and Testing

Digital twins are not just for design; they also enhance the engineering phase. Simulation and testing become more efficient, accurate, and cost-effective with this technology.

Utilizing digital twins for engineering involves multiple steps:

Performance Simulation

Digital twins enable engineers to run simulations of various performance aspects, such as fuel efficiency and acceleration. They can analyze the impact of different components and modifications on the overall vehicle performance.

Stress and Durability Testing

Simulating stress and durability helps engineers identify potential weak points in the vehicle structure. These simulations can replicate real-world conditions, allowing them to assess how the car will perform under various stressors.

These simulations contribute to:

- Enhanced vehicle safety

- Improved component longevity

- Optimized material selection

These simulations optimize the vehicle’s robustness and reliability.

Digital Twins in Manufacturing

Digital twins are integrated into the automotive manufacturing process for increased precision and efficiency. The benefits of this integration are transformative.

Integrating digital twins into manufacturing aims to:

Process Optimization

Digital twins provide a virtual representation of the entire manufacturing process, enabling manufacturers to identify bottlenecks, optimize workflows, and improve efficiency.

Predictive Maintenance

By monitoring the performance data of manufacturing equipment, digital twins can predict when maintenance is needed. This minimizes downtime and reduces unexpected breakdowns.

This integration helps to:

- Reduce manufacturing costs

- Improve product quality

- Enhance overall productivity

Predictive maintenance leads to efficient resource utilization and fewer disruptions.

Enhancing Vehicle Performance and Safety

One of the most significant advantages of using digital twins is the ability to enhance vehicle performance and safety. This technology serves as a valuable tool for understanding the complex interactions within a vehicle.

Vehicle performance and safety are improved by:

Aerodynamics Optimization

Digital twins allow engineers to simulate airflow around a vehicle, optimizing its aerodynamics to reduce drag and improve fuel efficiency. These simulations can identify areas where the design can be improved to enhance stability and speed.

Crash Simulation

Simulating crash scenarios allows engineers to assess the effectiveness of safety features, such as airbags and crumple zones. This enables them to fine-tune these features and improve occupant safety in the event of a collision.

Optimization also includes:

- Improved handling and stability

- Enhanced driver assistance systems

- Reduced risk of accidents

With digital twins, vehicles are not just designed to perform well, but also to keep occupants safe in unforeseen situations.

Challenges and Future Trends

While the benefits of digital twins are clear, several challenges need to be addressed to ensure their widespread adoption. Additionally, emerging trends point to exciting possibilities for the future of this technology.

Challenges and future trends include:

Data Integration and Management

Integrating data from various sources can be complex. Ensuring data accuracy, consistency, and security is crucial for creating reliable digital twins. Effective data management strategies are essential.

Computational Power

Running complex simulations requires significant computational power. Cloud computing offers a solution by providing scalable resources to handle these demanding workloads.

Artificial Intelligence (AI)

AI can enhance the capabilities of digital twins by enabling predictive analytics and automated decision-making. AI-powered digital twins can learn from data and continuously improve their accuracy and usefulness.

Emerging trends could also include:

- Improved data security protocols

- Better collaboration platforms

- More accessible simulation tools

As technology continues to evolve, digital twins will become even more powerful and indispensable in the automotive industry.

| Key Point | Brief Description |

|---|---|

| 🚗 Virtual Prototyping | Creating virtual car models to test design & performance before physical production. |

| ⚙️ Process Optimization | Using digital twins to identify manufacturing bottlenecks and improve efficiency. |

| 🛡️ Safety Enhancement | Simulating crash scenarios to improve vehicle safety features, such as airbags. |

| 🚀 Aerodynamic Improvements | Optimizing airflow to reduce drag and improve car performance. |

Frequently Asked Questions (FAQ)

▼

A digital twin is a virtual replica of a vehicle or component. It uses real-time data from sensors, simulations, and historical information to mirror its physical counterpart, allowing for predictive maintenance and design enhancements.

▼

Digital twins detect manufacturing process bottlenecks and predict equipment maintenance needs, cutting downtime significantly. This process optimization and preventive maintenance lead to reduced operational costs.

▼

Yes, digital twins can simulate crash scenarios and analyze the effectiveness of safety features like airbags and crumple zones. These simulations yield actionable insights to improve overall occupant safety in collisions.

▼

The main challenges include data integration from various sources, ensuring data reliability and security, and managing the high computational demands required for running complex simulations.

▼

Digital twins enable optimization in vehicle aerodynamics, fuel efficiency, and handling. They help engineers fine-tune designs ensuring exceptional performance in various driving conditions improving overall user experience.

Conclusion

In conclusion, digital twins are transforming automotive design and engineering by offering unprecedented capabilities in simulation, testing, and optimization. As technology evolves, these virtual replicas will continue to drive innovation, enhance vehicle performance, and ensure greater safety on the roads.